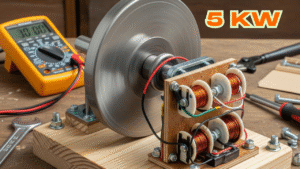

How to Make 220V 5kW Free Energy Generator Using 3 Coils, Wire No.18, 110 Turns, and One Magnet | DIY Home Project

Introduction

Generating electricity at home using a DIY system is a dream for many. With rising electricity bills and the need for sustainable energy, free energy generators have become a hot topic. But before we dive into the details, let’s make one thing clear: there is no truly “free energy” in the sense of violating the laws of physics. What we aim to achieve is highly efficient energy conversion using magnets and coils, based on the principle of electromagnetic induction.

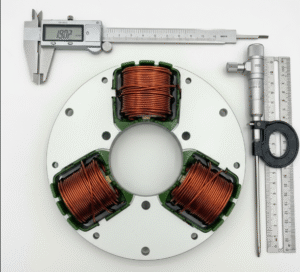

This project focuses on building a 220V 5kW generator using three coils, wire No.18 gauge, 110 turns each, and a single powerful magnet. If done correctly, this generator can power multiple household appliances.

⚠ Safety Warning: Working with high voltage (220V) is dangerous. Use protective gear, follow safety standards, and never test the generator near water or flammable materials.

Understanding the Principle of Operation

Electric generators work on the principle of Faraday’s Law of Electromagnetic Induction. When a magnetic field moves relative to a conductor, an electric current is induced in the conductor. In our case:

The magnet acts as the source of the magnetic field.

The coils made from copper wire act as the conductors.

When the rotor spins, it moves the magnet, causing magnetic flux to cut through the coil windings, generating alternating current (AC).

For higher voltage (220V) and power (5kW), the following factors matter:

Number of turns per coil (more turns = higher voltage)

Wire thickness (affects current handling capacity)

Magnet strength (stronger magnets induce more voltage)

RPM (rotations per minute of the rotor)

Materials Required

Copper Wire: Gauge 18 (SWG), ~3 kg for three coils

Coil Forms: Non-metallic cylindrical forms for winding

Permanent Magnet: Neodymium (high grade N52 recommended)

Rotor Plate: Steel disc or aluminum for mounting the magnet

Stator Plate: Non-magnetic base for fixing coils

Bearings and Shaft: For smooth rotation

Insulating Materials: Electrical tape, varnish

Output Terminals: For connecting the load

Tools: Winding jig, multimeter, soldering kit

Design Specifications

Coils: 3 identical coils

Wire: Copper No.18

Turns: 110 per coil

Core Material: Soft iron for better flux

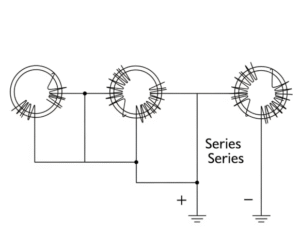

Connection: Series for higher voltage

Target Output: 220V AC at designed RPM

Power Handling: ~5kW at proper RPM

Why 3 coils? It ensures better distribution of flux and smoother AC waveform when positioned at 120° intervals around the rotor.

Step-by-Step Building Guide

Step 1: Prepare the Coils

Take your coil form and start winding copper wire No.18.

Wind 110 turns tightly and evenly.

After winding, secure the coil with insulating tape.

Apply varnish for durability.

Step 2: Build the Stator

Fix the three coils on a circular stator plate at equal distances (120° apart).

Ensure the cores are aligned toward the magnet path.

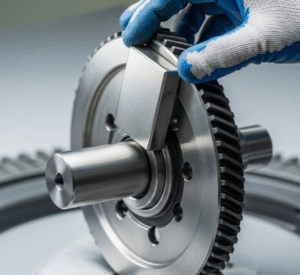

Step 3: Prepare the Rotor

Balance the rotor for smooth spinning.

Step 4: Assemble the Generator

Mount the rotor on a shaft with bearings.

Place the stator such that the rotor magnet passes close to the coils.

Maintain a 2–3 mm air gap for maximum efficiency.

Step 5: Connect the Coils

Wire the coils in series connection for maximum voltage.

Solder the terminals securely and insulate them.

Step 6: Add Output Terminals

Install heavy-duty connectors for 220V output.

If you plan to convert AC to DC, add a rectifier.

Step 7: Testing

Spin the rotor manually first and measure voltage using a multimeter.

Increase RPM using a drill or motor to reach 220V.

Add load gradually and monitor coil heating.

Troubleshooting

Low Voltage: Increase RPM or check coil connections.

Coil Overheating: Use thicker wire or better ventilation.

No Output: Magnet may not be strong enough or coils are shorted.

Efficiency Tips

Use Neodymium N52 magnets for maximum flux.

Minimize friction with high-quality bearings.

Use laminated cores to reduce eddy current losses.

Conclusion

Building a 220V, 5kW free energy generator at home requires knowledge of electricity, careful handling, and patience. This project demonstrates electromagnetic principles in action and, when optimized, can reduce dependence on the grid.

FAQs

| # | Question | Answer |

|---|---|---|

| 1 | What is a free energy generator? | It’s a device that converts mechanical energy into electrical energy using magnets and coils, based on electromagnetic induction. |

| 2 | Is this really free energy? | No. It requires input energy (mechanical rotation), but it can be highly efficient and reduce dependency on the grid. |

| 3 | Can I generate 220V at home with this? | Yes, if you follow proper design and maintain the required RPM for voltage output. |

| 4 | How many coils are used in this project? | Three coils, each with 110 turns of No.18 wire. |

| 5 | Why use No.18 wire? | It has the right thickness for handling current without overheating for moderate power output. |

| 6 | What magnet should I use? | A strong Neodymium magnet (preferably N52 grade) for maximum flux. |

| 7 | What is the purpose of 110 turns? | More turns increase voltage output. 110 turns are optimal for this design. |

| 8 | What is the expected power output? | Around 5kW if built correctly and rotated at proper RPM. |

| 9 | What RPM is needed for 220V? | Typically between 1500–3000 RPM depending on magnet strength and coil design. |

| 10 | How do I wind the coils? | Use a coil winder or manually wind the wire evenly around a form and secure with insulation tape. |

| 11 | Can I use thicker wire than No.18? | Yes, thicker wire can handle more current but will require fewer turns and larger coils. |

| 12 | Why only 3 coils? | Three coils provide better phase distribution and smooth AC waveform when arranged at 120° intervals. |

| 13 | Can I use more than 3 coils? | Yes, but that will increase complexity and size. |

| 14 | How big should the magnet be? | At least 2–3 inches in diameter and very strong for effective flux. |

| 15 | Can I use ferrite magnets? | No, ferrite magnets are too weak. Use Neodymium. |

| 16 | Do I need a rotor and stator? | Yes. The rotor carries the magnet, and the stator holds the coils in place. |

| 17 | What is the air gap between coils and magnet? | Ideally 2–3 mm for maximum flux transfer. |

| 18 | How do I balance the rotor? | Use counterweights or balancing tools to ensure smooth rotation. |

| 19 | Is it AC or DC output? | The generator produces AC. Use a rectifier if DC is needed. |

| 20 | Do I need an inverter? | Yes, if you want a stable 50/60Hz frequency for appliances. |

| 21 | Can this power my home? | Yes, if it truly produces 5kW and you use an inverter for stability. |

| 22 | What tools are required? | Coil winder, soldering kit, multimeter, drill machine, bearings, insulation tape. |

| 23 | How much does it cost to build? | Approximately $150–$250 depending on material quality. |

| 24 | Where can I buy Neodymium magnets? | Online marketplaces like Amazon, eBay, or specialized magnet suppliers. |

| 25 | How do I connect the coils? | In series for higher voltage, parallel for higher current. |

| 26 | How to measure output voltage? | Use a digital multimeter set to AC mode. |

| 27 | What happens if I reverse the coil wiring? | The phase will reverse, possibly reducing output. |

| 28 | How do I increase power output? | Use more powerful magnets, more coils, or increase RPM. |

| 29 | Why is my voltage too low? | Increase RPM, check coil winding, and ensure strong magnet alignment. |

| 30 | Why is my coil overheating? | Wire gauge too thin or overloading beyond its rating. |

| 31 | Can I use aluminum wire instead of copper? | Not recommended. Copper is more efficient and has better conductivity. |

| 32 | Do I need a laminated core? | Yes, for reducing eddy current losses and improving efficiency. |

| 33 | How many amps will it produce? | Around 22A at 220V if producing full 5kW output. |

| 34 | What size shaft is needed? | At least 1-inch diameter for strength and stability. |

| 35 | What bearings should I use? | High-speed ball bearings for smooth rotation. |

| 36 | Can I run this without a load? | Yes, but output voltage may spike dangerously. Use a dummy load for testing. |

| 37 | Can I use this to charge batteries? | Yes, with a rectifier and charge controller. |

| 38 | Is it safe for beginners? | Only if you have basic electrical knowledge and follow safety precautions. |

| 39 | What is the lifespan of the generator? | Depends on bearing quality and maintenance, typically 5–10 years. |

| 40 | Can I make it portable? | Yes, but weight and size might be a factor. |

| 41 | Can I use magnets from old speakers? | No, they are too weak for this project. |

| 42 | How to make it weatherproof? | Enclose in a waterproof casing with ventilation. |

| 43 | How do I calculate wire length? | Turns × coil circumference = total wire length per coil. |

| 44 | Can I build this without a lathe? | Yes, if you buy pre-made rotor and stator parts. |

| 45 | How to mount the stator? | Use a rigid frame to prevent vibration. |

| 46 | Can this run 24/7? | Yes, if properly lubricated and ventilated. |

| 47 | Can I connect it to the grid? | Only with proper grid-tie inverter and permission from authorities. |

| 48 | Will this work in low RPM? | No, voltage will be too low. Use higher RPM for desired output. |

| 49 | Can I make it silent? | Yes, by using good bearings and balancing the rotor. |

| 50 | Can I power an air conditioner with this? | Yes, if it produces stable 220V AC at sufficient wattage. |

For Example Video