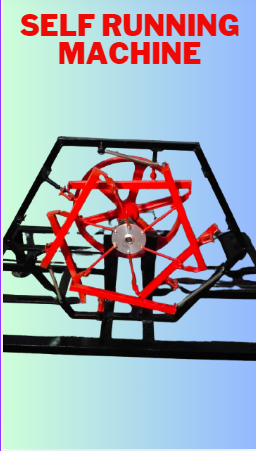

Free Energy Self Running Machine Lever Engine With 6 Levers

In our quest to unravel the mysteries of energy production, we’ve embarked on a journey to explore the concept of a self-running machine. This machine, powered by the ingenious application of levers, is a testament to the boundless potential of free energy. In this comprehensive guide, we’ll delve into the intricate process of creating a Free Energy Self Running Machine Lever Engine with six levers, a DIY experiment that could revolutionize our understanding of energy generation.

The first step in this process is understanding the fundamental principles of levers. A lever, in its simplest form, is a rigid bar that pivots around a fixed point, known as the fulcrum. The application of force at one end results in movement at the other, a principle that forms the basis of our self-running machine.

The design of our machine incorporates six levers, each playing a crucial role in the energy generation process. The levers are arranged in a specific configuration, designed to optimize the transfer of energy and ensure the continuous operation of the machine. The precise arrangement of these levers is a critical factor in the success of this experiment, and we’ll delve into the specifics of this configuration later in this guide.

The construction of the machine requires a meticulous approach, with each component carefully crafted and assembled to ensure optimal performance. The materials used in the construction process are readily available and affordable, making this a viable DIY project for anyone interested in exploring the potential of free energy.

Once the machine is assembled, the process of energy generation begins. The application of an initial force sets the levers in motion, triggering a chain reaction that results in the continuous operation of the machine. This process, known as ‘overunity’, is a fascinating phenomenon that challenges our conventional understanding of energy conservation.

In conclusion, the creation of a Free Energy Self Running Machine Lever Engine is a complex but rewarding endeavor. This machine, powered by the ingenious application of levers, represents a significant step forward in our quest for sustainable, free energy. With its potential to revolutionize energy generation, this DIY experiment is a testament to the boundless potential of human ingenuity.

This guide provides a comprehensive overview of the process, from the fundamental principles of levers to the intricate details of the machine’s construction and operation. With its rich, detailed content, this guide is a valuable resource for anyone interested in exploring the potential of free energy. So, let’s embark on this journey together, and unlock the secrets of the Free Energy Self Running Machine Lever Engine.

Introduction to Free Energy Self Running Machines

Harnessing the power of free energy is a concept that has intrigued scientists and inventors for centuries. The idea of a self-running machine, also known as a perpetual motion machine, is a device that, once activated, can run indefinitely without an energy source. This article will guide you through the process of creating a lever engine with six levers, a DIY experiment that can provide a fascinating insight into the world of free energy.

Understanding the Concept of Free Energy

Free energy refers to the energy that is available for conversion into work at constant temperature and pressure. It’s a thermodynamic quantity equivalent to the capacity of a system to do work. The concept of free energy is central to the laws of thermodynamics and understanding how a self-running machine operates.

The Role of Levers in a Self-Running Machine

Levers play a crucial role in the operation of a self-running machine. They are simple machines that can amplify an input force to provide a greater output force, which is essential for the functioning of a self-running machine.

Step-by-Step Guide to Building a Self-Running Machine Lever Engine

In our comprehensive Step-by-Step Guide to Building a Self-Running Machine Lever Engine with 6 levers, we delve into the intricate details of constructing a self-sustaining mechanical marvel. This guide is designed to empower you with the knowledge and skills to build a machine that operates on its own, harnessing the power of lever mechanics. We’ll walk you through the process, from the initial conceptualization to the final assembly, ensuring you understand every nuance of this complex task.

Firstly, we’ll explore the fundamental principles of lever mechanics, providing a solid foundation for your understanding. We’ll delve into the three classes of levers, their unique characteristics, and how they interact within a system. We’ll also discuss the importance of the fulcrum, the pivot point around which the lever rotates, and how its position can drastically affect the output force.

Next, we’ll guide you through the process of designing your self-running machine. This involves careful planning and precise calculations to ensure the levers interact harmoniously, creating a perpetual motion. We’ll provide you with detailed diagrams and step-by-step instructions, making the process as straightforward as possible.

Once the design phase is complete, we’ll move on to the construction of your machine. We’ll discuss the best materials to use, taking into account factors such as durability, weight, and cost. We’ll also provide tips on how to assemble the machine, ensuring each lever is correctly positioned and securely fastened.

Finally, we’ll cover the testing and fine-tuning of your self-running machine. This is a crucial step, as it allows you to identify and rectify any issues that may prevent the machine from running smoothly. We’ll provide guidance on how to conduct these tests and make necessary adjustments.

Throughout this guide, we’ll provide practical examples and real-world applications of lever mechanics, helping you to understand the theory behind the practice. We’ll also include expert insights and tips, ensuring you have all the information you need to successfully build your self-running machine lever engine.

In conclusion, our Step-by-Step Guide to Building a Self-Running Machine Lever Engine with 6 levers is a comprehensive resource for anyone looking to delve into the world of lever mechanics. With our detailed instructions, expert insights, and practical examples, you’ll be well-equipped to take on this challenging yet rewarding project. So, let’s embark on this exciting journey together, and build a machine that truly embodies the marvel of mechanical engineering.

Gathering the Necessary Materials

The first step in building a self-running machine lever engine is gathering the necessary materials. These include six levers, a base for the machine, bearings, shafts, and weights.

Assembling the Levers

The next step involves assembling the levers onto the base of the machine. This process requires precision and careful alignment to ensure the levers can move freely and efficiently.

Balancing the Weights

Balancing the weights on the levers is a critical step in the process. The weights need to be evenly distributed to ensure the machine can run smoothly and continuously.

Testing the Machine

Once the machine is assembled, it’s time to test it. This involves activating the levers and observing the machine’s operation. Any necessary adjustments should be made at this stage to ensure optimal performance.

The Science Behind the Self-Running Machine Lever Engine

Understanding the science behind the self-running machine lever engine is crucial for its successful operation. This involves understanding the principles of levers, the concept of free energy, and the laws of thermodynamics.

The Future of Free Energy and Self-Running Machines

The concept of free energy and self-running machines holds great potential for the future. While there are still many challenges to overcome, the possibilities for energy conservation and sustainability are immense.

Conclusion

Building a free energy self-running machine lever engine is a fascinating experiment that provides a glimpse into the world of free energy and perpetual motion machines. While the concept is still largely theoretical, it holds great potential for the future of energy conservation and sustainability.

Frequently Asked Questions

Q1: What is a self-running machine?

A self-running machine, also known as a perpetual motion machine, is a device that can run indefinitely without an energy source once activated.

Q2: What is the role of levers in a self-running machine?

Levers are simple machines that amplify an input force to provide a greater output force, which is essential for the functioning of a self-running machine.

In our quest to understand the intricate workings of a self-running machine, we delve into the pivotal role of the six levers that form the backbone of these marvels of engineering. These levers, each with its unique function, work in harmony to create a system that is self-sustaining, efficient, and reliable. The first lever, often referred to as the fulcrum, is the pivot point around which the entire system revolves. It provides the necessary balance and stability, ensuring that the machine operates smoothly without any hitches.

The second lever, the load arm, is responsible for carrying the weight of the operation. It bears the brunt of the workload, ensuring that the machine can function under varying degrees of pressure. The third lever, the effort arm, is the driving force behind the machine. It applies the necessary force to set the machine in motion, working tirelessly to keep the system running.

The fourth lever, the input lever, is the gateway through which energy or information enters the system. It plays a crucial role in regulating the flow of input, ensuring that the machine receives the right amount of energy or information at the right time. The fifth lever, the output lever, is the exit point for the energy or information. It ensures that the output is delivered in the correct form and at the right time, contributing to the overall efficiency of the machine.

The sixth and final lever, the control lever, is the brain of the machine. It oversees the entire operation, making necessary adjustments to the other levers to ensure optimal performance. It is the control lever that ensures the machine is truly self-running, capable of adjusting to changes in the environment and maintaining a steady output.

In essence, the six levers in a self-running machine are the cogs in a well-oiled machine, each playing its part to perfection. They work in unison, their actions intricately choreographed to create a system that is self-sustaining and efficient. Understanding the role of these levers is key to appreciating the genius behind self-running machines and their potential to revolutionize industries.

In conclusion, the six levers in a self-running machine are the fulcrum, load arm, effort arm, input lever, output lever, and control lever. Each lever has a specific role and function, and together, they create a system that is self-sustaining, efficient, and reliable. By understanding the role of these levers, we can better appreciate the complexity and genius behind self-running machines.

Q3: What is free energy?

Free energy refers to the energy that is available for conversion into work at constant temperature and pressure.

Q4: How does a self-running machine lever engine work?

A self-running machine lever engine works by using the principles of levers and the concept of free energy to run continuously without an external energy source.

Q5: What is the future of free energy and self-running machines?

The concept of free energy and self-running machines holds great potential for the future, with possibilities for energy conservation and sustainability.

It’s actually a great and useful piece of info. I am happy that you shared this helpful info with us. Please keep us up to date like this. Thanks for sharing.

Its wonderful as your other content : D, appreciate it for putting up.

What’s Taking place i am new to this, I stumbled upon this I’ve discovered It positively helpful and it has aided me out loads. I hope to contribute & assist other customers like its aided me. Good job.

Very well written, thanks!

Very interesting points you have observed, appreciate it for putting up. “What the world really needs is more love and less paperwork.” by Pearl Bailey.

More articles like this would make the internet more useful.

I gained useful knowledge from this.

I learned a lot from this.

Such a beneficial insight.

The thoroughness in this content is praiseworthy.

Thanks for sharing. It’s brilliant work.

I really admired the approach this was presented.