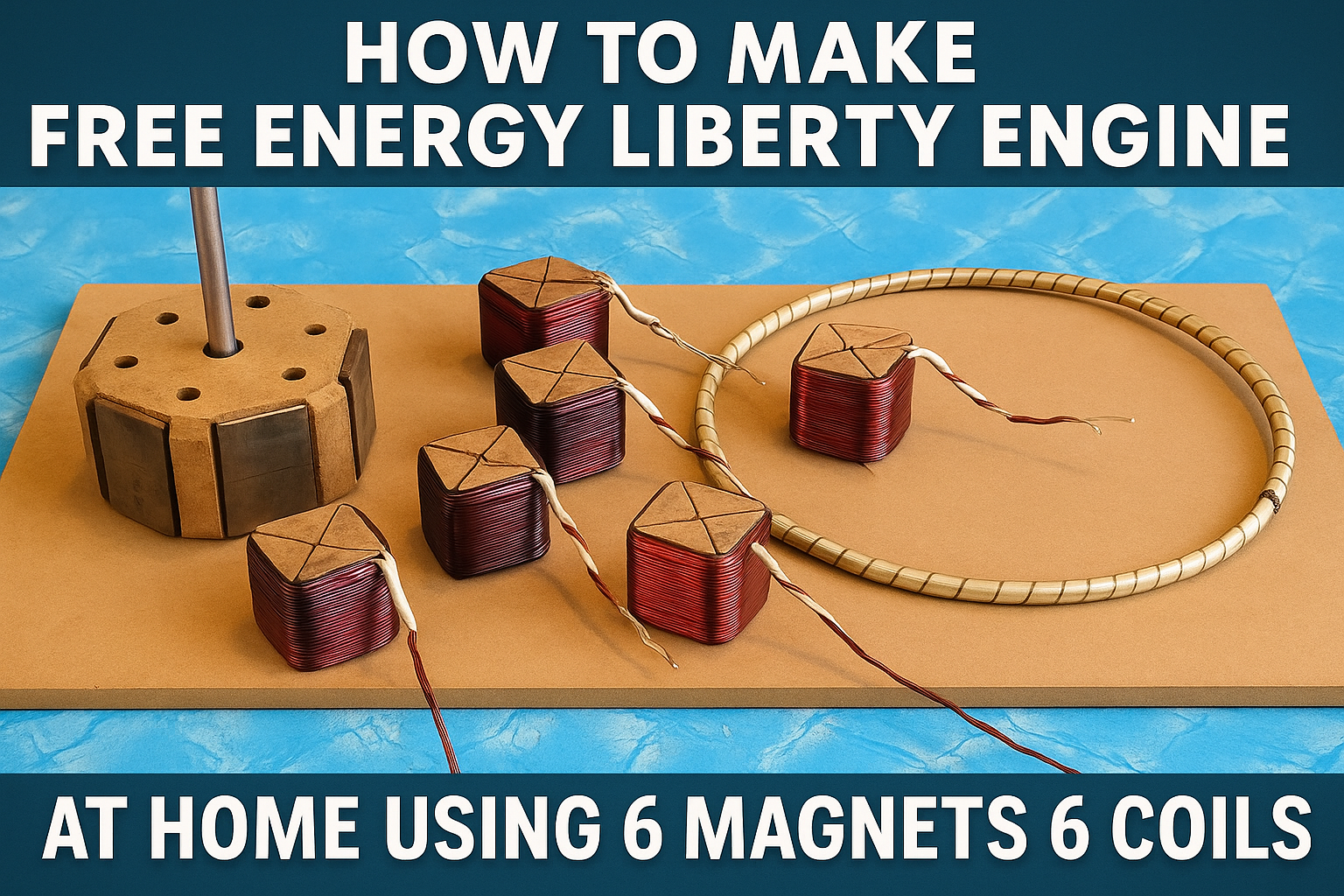

How To Make a FREE ENERGY LIBERTY ENGINE at Home Using 6 Magnets and 6 Coils

Table of Contents

Introduction to Free Energy

Understanding the Liberty Engine Concept

Materials and Tools You’ll Need

Core Principles: Magnetic Induction & Coils

Step-by-Step Liberty Engine Construction Guide

Wiring & Connections

Testing the Output

Safety Measures

Troubleshooting Common Issues

Efficiency Optimization Tips

Realistic Expectations & Limitations

Legal & Ethical Considerations

FAQs

Conclusion

1. Introduction to Free Energy

The idea of free energy liberty engine has fascinated inventors and engineers for decades. While traditional electricity depends on fuel consumption or solar, wind, or water sources, free energy devices aim to use magnetic and inductive properties to create self-sustaining systems. One of the latest DIY trends is the Liberty Engine, a magnet-based motor generator system that’s designed for home experimentation.

While the term “free energy” doesn’t mean breaking the laws of thermodynamics, it refers to systems that reduce or recycle energy loss to increase overall efficiency — especially through permanent magnets and electromagnetic induction.

2. Understanding the Liberty Engine Concept

A Liberty Engine is a type of homemade generator that uses:

Permanent magnets (to provide a constant magnetic field)

Copper coils (to induce current through motion)

A rotor/stator setup (to generate relative motion)

This design relies on the interaction between magnets and coils — where motion between the two induces electrical current in the coil windings (Faraday’s Law).

This DIY project uses:

6 neodymium magnets arranged on a rotor

6 copper wire coils mounted on a stator or base

When set in motion (manually or with an external push), the rotor’s magnets create fluctuating magnetic fields through the stationary coils — thus generating alternating current (AC).

3. Materials and Tools You’ll Need

🔧 Basic Materials:

6 Neodymium magnets (cylindrical or disc-shaped)

6 Copper wire coils (enameled, 24–28 AWG, 500 turns per coil)

1 Rotor disc (acrylic, plastic, or plywood)

1 Stator base (non-metallic, stable material)

1 Steel shaft (for rotation)

2 Ball bearings (for smooth motion)

1 Bridge rectifier (to convert AC to DC)

1 Capacitor or battery (to store output)

Glue gun, screws, nuts, washers

⚙️ Tools:

Drill machine

Soldering iron

Multimeter

Hot glue gun

Wire stripper

Ruler and compass

4. Core Principles: Magnetic Induction & Coils

💡 Faraday’s Law of Electromagnetic Induction:

Whenever a magnetic field moves past a coil (or a coil moves past a magnet), an electric current is induced in the coil. This is the basic principle of electric generators.

🧲 Role of Magnets:

Neodymium magnets are ideal because of their strong field. Their movement over coils produces significant voltage spikes.

🌀 Coil Construction:

Each coil must be uniformly wound and insulated with enamel. 500 turns is ideal for household-level generation. More turns = more voltage but less current.

5. Step-by-Step Liberty Engine Construction Guide

🔨 Step 1: Design Layout

Draw a circle (rotor) and mark 6 equidistant points on the circumference.

The magnets will be placed at these positions with alternating polarity: N–S–N–S–N–S

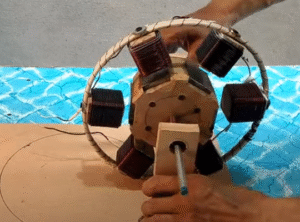

🔨 Step 2: Construct the Rotor

Fix the 6 magnets onto the rotor with glue or epoxy.

Ensure all magnets are securely attached and the polarity alternates.

Drill a center hole in the rotor for the shaft.

🔨 Step 3: Build the Stator Base

Mount 6 coils on a stable surface forming a circle aligned with the rotor.

Leave about 2–3mm gap between coils and magnets.

Secure the coils using hot glue.

🔨 Step 4: Install Bearings & Shaft

Insert the steel shaft through the rotor.

Place ball bearings at both ends to ensure smooth, low-friction rotation.

Mount the rotor on a stand (wood or plastic frame).

6. Wiring & Connections

🧷 Coil Wiring:

Wire the 6 coils in series or parallel, depending on the desired voltage/current.

Series = Higher voltage, lower current

Parallel = Higher current, lower voltage

🔌 Add Rectifier and Capacitor:

Connect the coil outputs to a bridge rectifier.

The rectifier outputs DC.

Connect a capacitor or 12V battery to store energy.

📏 Testing Voltage:

Use a multimeter to measure AC at coil output and DC after the rectifier. A well-balanced setup can produce 5V to 20V with minimal RPM.

EXPERIMENT

7. Testing the Output

✅ Test 1: Manual Spin

Spin the rotor manually and check coil output.

Multimeter should detect alternating current across each coil.

✅ Test 2: Drill Motor Spin

Use a drill machine to spin the rotor at a constant RPM.

Measure voltage before and after the rectifier.

✅ Test 3: Lighting a Load

Try powering an LED or small fan.

If successful, your Liberty Engine is working!

8. Safety Measures

While building and testing:

Keep magnets away from electronics and credit cards.

Use insulated gloves when handling wires.

Don’t short the capacitor — it can explode.

Avoid spinning the rotor too fast — can damage coils.

9. Troubleshooting Common Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| No voltage output | Magnet polarity is not alternating | Rearrange magnets |

| Low voltage | Coil turns too low | Increase turns to 500–1000 |

| Rotor not spinning freely | Shaft or bearing misalignment | Re-check mounting and balance |

| Heat in rectifier or capacitor | Overload or short circuit | Add current-limiting resistor |

| Output drops after few seconds | Poor coil soldering or loose joints | Inspect and fix all electrical contacts |

10. Efficiency Optimization Tips

Increase coil turns to raise voltage output.

Use magnetic shielding to prevent field leakage.

Balance rotor weight to avoid wobbling.

Use graphite lubricant on bearings for smoother motion.

Align magnets and coils precisely to reduce flux losses.

Optional:

Add a mechanical crank or DC motor to automate rotation.

Use MPPT charge controller if connecting to a battery.

11. Realistic Expectations & Limitations

While this project is great for learning and experimentation, it’s important to understand:

You won’t power your whole house.

It can power LEDs, small fans, mobile chargers, etc.

Continuous rotation requires manual or external energy.

It’s not perpetual motion — it’s a high-efficiency generator using kinetic energy input.

12. Legal & Ethical Considerations

Before connecting the Liberty Engine to a home circuit:

Do NOT connect it directly to mains.

Avoid misleading claims about “infinite energy.”

This device is for educational and experimental use only.

Respect local energy regulations and safety standards.

13. FAQs

❓ Can this Liberty Engine run by itself?

No. You need to spin the rotor manually or via motor. It’s not a perpetual motion machine.

❓ How much energy can I store?

Depends on coil quality, speed of rotation, and rectifier-capacitor setup. Usually enough for low-wattage devices.

❓ Can I increase magnet or coil count?

Yes! You can scale up to 12 magnets and 12 coils for higher output, but it requires better alignment and stronger support.

❓ How long will the magnets last?

Neodymium magnets can last 10–20 years without losing strength unless exposed to high heat.

14. Conclusion

Creating a Free Energy Liberty Engine using 6 magnets and 6 coils is not only a rewarding DIY project but also a hands-on educational tool for understanding the science of energy generation.

While it’s not a replacement for conventional power systems, it’s a great way to explore:

Magnetism

Electromagnetic induction

Alternative energy experimentation

By following the steps above carefully, you’ll build a working prototype capable of producing real electricity — proving that with the right components, even a beginner can create power from motion.

Your blog is a true gem in the world of online content. I’m continually impressed by the depth of your research and the clarity of your writing. Thank you for sharing your wisdom with us.

The matchless theme, is pleasant to me 🙂