<!doctype html>

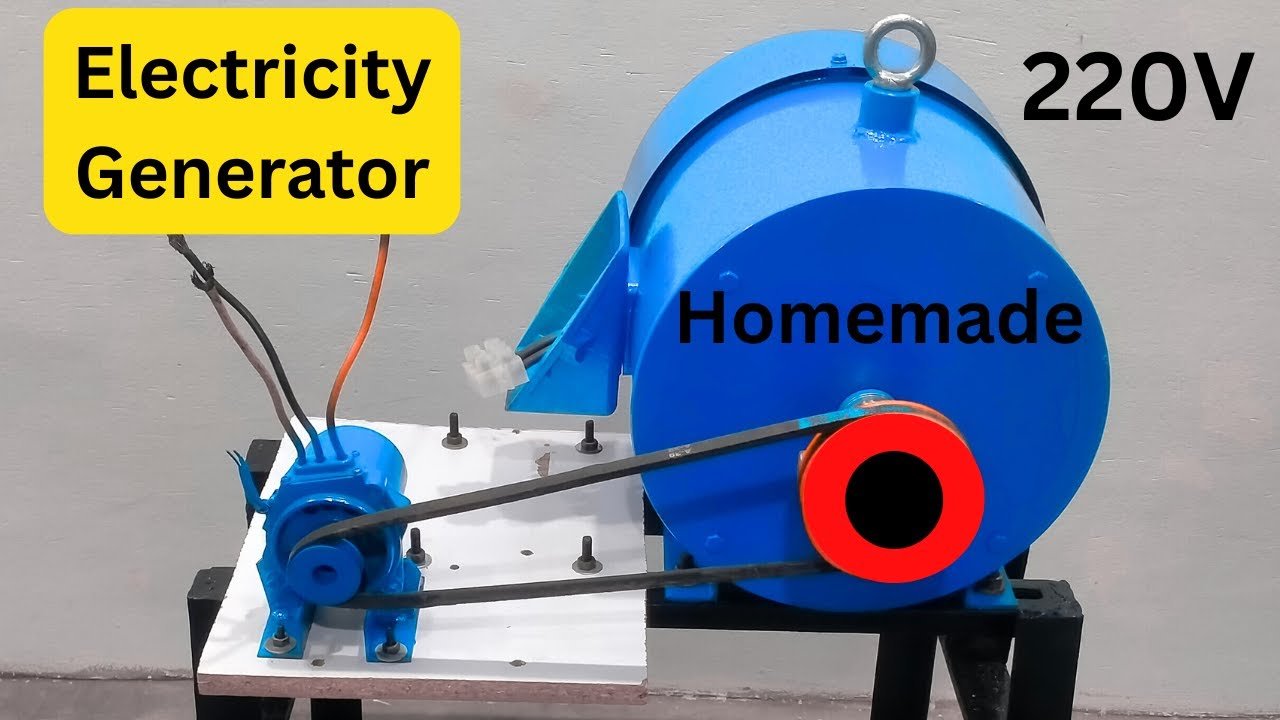

How To Make 15 KW Electricity Generator With 20 HP BLDC Motor At Home

Short summary: This guide walks you through building a 15 kW generator using a 20 HP BLDC motor as the main alternator and a 1 kW BLDC motor as the driving motor. It includes parts, mechanical coupling, electrical wiring, safety precautions, testing, maintenance and frequently asked questions. Read the safety section carefully before attempting any wiring or high-power testing.

Table of contents

- Introduction

- Why choose BLDC motors

- Parts & tools list

- Design overview & power math

- Mechanical build (frame, coupling, alignment)

- Electrical wiring (rectifier, inverter, batteries)

- Testing and commissioning

- Safety & troubleshooting

- Maintenance and upgrades

- 20 FAQs

- Conclusion

Introduction

Generating 15 kW of electrical power at home is an ambitious but achievable DIY project if you have mechanical skills, electrical knowledge and the right components. In this project we use a commercially available 20 HP BLDC motor (≈ 15 kW nominal) as the generator (alternator) and a 1 kW BLDC motor to drive it. The small BLDC acts as a prime-mover in a test/experimental setup where grid connection or renewable prime movers are not used. The key idea: when a BLDC motor is mechanically driven at appropriate RPM and excitation, it will act as a generator and produce electrical power.

Why use BLDC motors for this project?

- High efficiency due to low friction and no brushes.

- Good power density — more power for smaller size compared with old brushed motors.

- Low maintenance because there are no brushes to replace.

- Bi-directional operation — they can run as motor or generator with suitable electronics.

Parts & tools (complete shopping list)

Buy good-quality components — poor parts cause inefficiency, heat, or hazard.

Major components

- 20 HP BLDC motor (rated for continuous duty; ideally IP-rated for dust/water resistance)

- 1 kW BLDC motor (as driver; must have a compatible controller)

- Two BLDC motor controllers (speed controller / ESC for the 1 kW, and an appropriate controller/rectifier arrangement for the 20 HP when used as generator)

- 15 kW inverter (pure sine wave grid-tie or off-grid inverter depending on your plan)

- Battery bank (48 V or 96 V typical — capacity sized to your needs; for heavy loads a large AH rating is required)

- Charge controller (if charging batteries from generator output)

- Rectifier / AC-DC converter (if the 20 HP produces AC waveforms you need controlled rectification before battery charging)

- Heavy-duty fuse / circuit breaker panel

- Mechanical coupling (flexible direct-coupler or V-belt & pulleys)

- Mounting frame and base (steel welded frame recommended)

- Cooling — fans or water jacket if continuous full-load operation planned

- Vibration isolators to reduce stress on mounts

Supporting materials & tools

- Copper power cables (appropriately sized for 15 kW currents)

- Control wiring, connectors, lugs and heatshrink

- Multimeter, clamp meter and oscilloscope (recommended)

- Welding machine, drill, grinders, hacksaw

- Torque wrench and shaft alignment tools

- Personal protective equipment (PPE): gloves, goggles, insulated tools

Design overview & power math

Understand the numbers before building:

- 20 HP ≈ 14.92 kW (1 HP = 746 W). In practice, nameplate 20 HP correlates to roughly 15 kW mechanical power.

- Expect electrical output to be somewhat less than mechanical input due to generator losses — aim for a 15 kW electrical target with realistic efficiency assumptions (80–90%).

- The 1 kW BLDC driver cannot supply 15 kW of continuous mechanical input — in this build the 1 kW motor is used as the prime mover only in an experimental bench configuration or to spin the larger motor at low power for testing. For full 15 kW continuous operation you’ll need a proper prime mover (diesel engine, turbine, large motor used as motor powered by battery pack or renewable input). If you intend to run completely off-grid without an external mechanical source, you must provide enough mechanical horsepower to match the generator’s required torque and RPM.

Mechanical build

Frame & mounting

Use a welded steel frame sized to isolate vibration and support the shafts. The generator and driver should be aligned on the same horizontal plane. Use rigid motor mounts and vibration isolators under the base.

Shaft coupling & alignment

Direct coupling is preferred for best efficiency: a flexible jaw coupling or a precision spline coupling will reduce misalignment stress. If space or torque multiplication is needed, use a pulley and V-belt system — choose pulley diameter ratio to achieve desired RPM on the generator.

Bearings & lubrication

Ensure bearings are rated for the radial and axial loads you expect. Proper lubrication schedule will greatly increase life — follow the motor manufacturer’s recommendation.

Electrical wiring & control

Generator output type

BLDC motors may produce multi-phase AC (e.g., three-phase) waveforms when spun. To use the output for battery charging or for an inverter you will likely need controlled rectification and smoothing:

- Rectifier (three-phase bridge) to convert AC to DC for battery charging.

- DC bus filtering capacitors and bus bar to stabilize DC before the inverter.

- Charge controller to manage battery charging and prevent overcharge.

Inverter selection

Choose an inverter sized above your maximum load (a 15 kW inverter with a 20–25% surge margin is recommended). Decide whether you need grid-tie (requires utility permission) or off-grid inverter with transfer switching. Make sure the inverter’s DC input voltage matches your battery bank and the rectified generator output.

Wiring and protection

- Size cables for expected current: at 230 V and 15 kW, current ≈ 65 A. For 120 V, current ≈ 125 A — choose conductor sizes and breakers accordingly.

- Install fuses, MCCBs and an emergency stop switch close to the system.

- Implement proper earthing/grounding for safety and electromagnetic protection.

Control strategy & running the system

The simplest control strategy is:

- Spin the 20 HP BLDC to target RPM using the prime mover.

- Rectify generator output into DC and charge batteries or feed the DC bus.

- Let the inverter convert DC bus voltage to AC mains for loads.

- Use monitoring (voltmeter, ammeter, temperature sensors) and automatic shutdown logic for overloads.

Testing & commissioning

Follow a controlled step-by-step test plan:

- Verify mechanical alignment and that all fasteners are torqued correctly.

- With no electrical load, spin the generator to rated RPM and check phase voltages and symmetry with an oscilloscope or three-phase meter.

- Connect rectifier and check DC bus voltage. Test charge controller behavior at low charging currents first.

- Gradually apply resistive loads (heaters or banked light bulbs) while monitoring current, voltage, and temperature.

- Ramp loads up to planned maximum while watching for heating, vibration, or electrical instability.

Safety checklist

- Double-check grounding connections.

- Install thermal sensors on motor housings and controller heatsinks.

- Use emergency stop that cuts DC bus and prime mover power.

- Keep clear of rotating shafts and install guards around couplings and belts.

- Label all circuits and place warning signs for high-voltage areas.

Troubleshooting (common issues)

Low output voltage

Possible causes: insufficient RPM, loose wiring, worn magnets, poor coupling alignment. Fix: increase RPM, inspect couplings, re-tighten connections.

Overheating

Causes: overcurrent, blocked ventilation, poor duty-cycle. Fix: improve cooling, reduce load, check winding insulation.

Voltage fluctuations

Causes: unstable RPM from prime mover, loose mechanical parts, poor DC bus filtering. Fix: stabilize prime mover control, add capacitance or smoothing, tighten mechanical mounts.

Maintenance schedule

- Monthly: visual inspection, check fasteners and wiring tightness.

- Quarterly: test insulation resistance, inspect bearings and lubricant levels.

- Annually: full teardown inspection, replace worn bearings, test controllers and inverter for efficiency.

Upgrades & alternatives

- Add renewable prime movers: couple the 20 HP generator to a wind turbine or hydro system for truly sustainable generation.

- Use a larger prime mover (e.g., a 25–30 kW engine or motor) if continuous 15 kW output is required without stressing components.

- Implement smart inverter controls and remote monitoring for load management and predictive maintenance.

FAQs — 20 common questions

Q1: Can a BLDC motor act as a generator?

A: Yes. When a BLDC motor is mechanically driven it produces multi-phase electrical output. This output can be rectified and conditioned for battery charging or inverter input.

Q2: Is a 1 kW motor enough to drive a 20 HP generator?

A: No — a 1 kW motor cannot continuously supply 15 kW. In practice the 1 kW motor is useful only for low-power testing and proof-of-concept. For continuous full-load operation you need a prime mover capable of delivering the required mechanical power.

Q3: What RPM should the 20 HP BLDC be run at?

A: Run it at the RPM specified by the motor’s electrical/phase design for desired voltage. Check the motor datasheet: BLDC characteristics vary by pole count and winding, so target the rated speed that produces rated voltage at no-load.

Q4: Do I need special electronics to use a BLDC as generator?

A: Yes. You will likely need a rectifier, DC bus filtering, and a charge/inverter system to make the generator output usable for loads or battery charging.

Q5: Can I grid-tie this generator?

A: Only with a certified grid-tie inverter and permission from your utility. Grid interconnection has regulatory and safety requirements — consult local utility rules and electrical codes.

Q6: How much will this project cost?

A: Costs vary widely. A new 20 HP BLDC may cost several hundred to over a thousand dollars depending on supplier and quality. Add in inverter, batteries, controllers and materials — a rough estimate for a modest system could be USD 3,000–10,000 depending on specifications and whether you source used components.

Q7: Is this a “free energy” project?

A: No. Energy conservation obeys physics: producing 15 kW electrical requires corresponding mechanical input (and losses). This is a conversion system — using renewable prime movers can reduce fuel cost but not violate energy conservation.

Q8: What kind of batteries should I use?

A: For heavy-duty use choose deep-cycle lithium (LiFePO4) or sealed lead-acid depending on budget. Match inverter DC voltage and size capacity (Ah) to desired runtime.

Q9: How do I size the inverter?

A: Choose an inverter rated for continuous power ≥ your peak expected load (15 kW) and include surge capacity for motors and compressors. A 20 kW inverter gives margin for startup currents.

Q10: What’s the expected efficiency?

A: System efficiency from mechanical input to AC output can be 75–90% depending on component quality and losses in rectification, inverter and bearings.

Q11: Can I use a petrol/diesel engine to drive the 20 HP motor?

A: Yes. Coupling an engine via a shaft or gearbox is common for continuous high-power applications. Ensure proper coupling and torque matching.

Q12: How do I protect against overcurrent?

A: Use correctly rated fuses, circuit breakers, and electronic current-limiting features in your controllers.

Q13: Can the 20 HP BLDC be used directly as a motor too?

A: Yes — BLDCs are reversible. The same machine can operate as a motor or generator with the right controller and supply.

Q14: Is special grounding required?

A: Yes — because both DC and AC systems exist in the same installation proper grounding and bonding prevents shock and interference. Follow local electrical code.

Q15: What are the common failure points?

A: Bearings, insulation breakdown, overheating of controllers/inverters, loose mechanical couplings and poor stator/rotor magnet conditions.

Q16: How long can it run continuously?

A: With adequate cooling and correct maintenance, continuous runs for many hours are possible. Duty cycle depends on motor and controller ratings.

Q17: How do I measure generated power?

A: Use a properly rated wattmeter or clamp meter monitoring both voltage and current on the output/inverter side. Logging instruments help record performance over time.

Q18: Can I parallel multiple BLDC generators?

A: Paralleling power electronics (inverters) is possible if they support synchronization and load sharing. Direct paralleling of raw generator AC outputs is NOT recommended without proper synchronization hardware.

Q19: Do I need an isolation transformer?

A: An isolation transformer can help with safety and grounding scheme choices, and can provide step-up or step-down voltage matching.

Q20: Should I get professional help?

A: Yes — for final wiring, protection coordination and grid-interconnection consult a licensed electrician or electrical engineer.

Conclusion

Building a 15 kW generator using a 20 HP BLDC motor is a challenging but rewarding project. Careful selection of components, proper mechanical alignment, correctly sized power electronics and strict adherence to electrical safety standards are essential. Use this guide as a blueprint, but validate every step against datasheets and local electrical regulations. If in doubt, seek professional assistance for high-power wiring and grid connection.