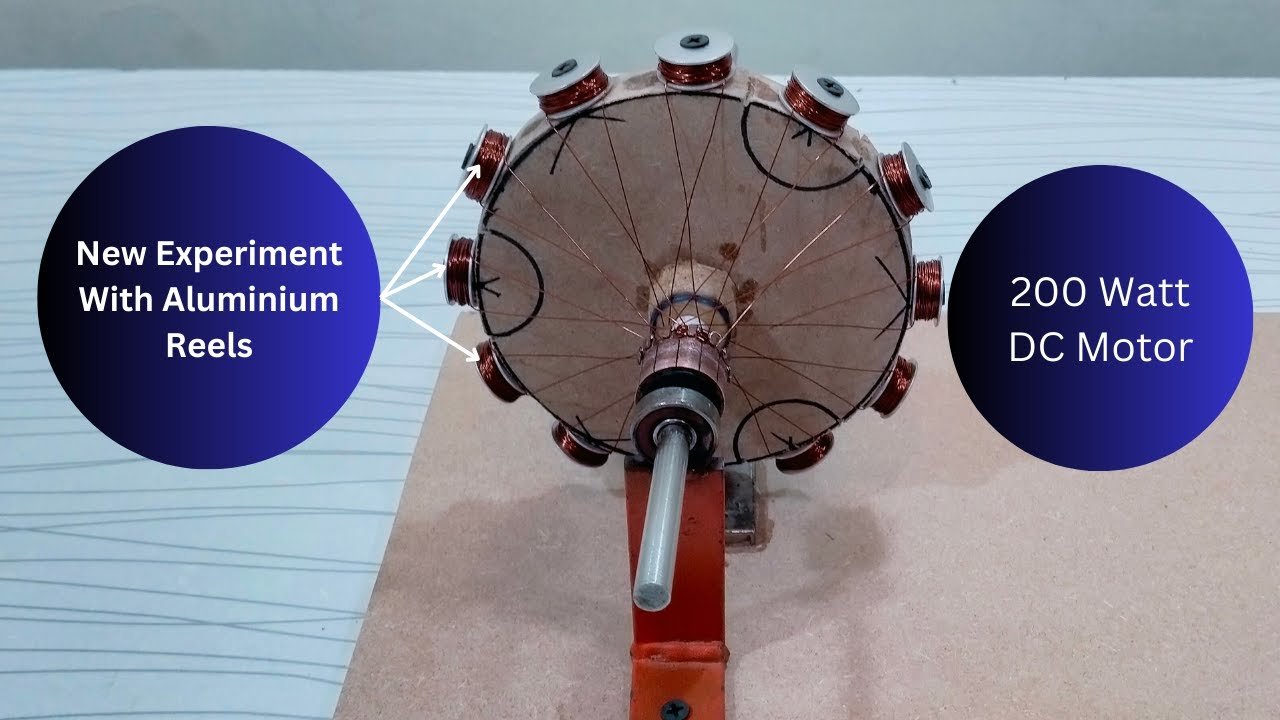

Unveiling the New Experiment: Making a 200 Watts DC Motor 220 Volt with 12 Aluminium Reels, 12 Screws, and a Magnet

Introduction to the Innovative Experiment

In the realm of electrical engineering, the creation of a 200 Watts DC Motor 220 Volt using 12 Aluminium Reels, 12 screws, and a magnet is a groundbreaking experiment. This innovative approach not only challenges conventional methods but also opens up new possibilities for energy efficiency and sustainability.

The Core Components: Aluminium Reels, Screws, and Magnet

The heart of this experiment lies in the unique combination of 12 Aluminium Reels, 12 screws, and a magnet. These components, when assembled correctly, can generate a powerful 200 Watts DC Motor 220 Volt.

The Role of Aluminium Reels

Aluminium reels play a crucial role in this experiment. They serve as the primary conductive material, allowing the flow of electric current. Their lightweight nature and high conductivity make them an ideal choice for this experiment.

The Significance of Screws

The 12 screws used in this experiment are not just ordinary screws. They are integral to the assembly of the motor, providing the necessary mechanical strength and stability.

The Power of the Magnet

The magnet is the driving force behind the motor. It creates the magnetic field necessary for the motor to function. The strength and quality of the magnet directly influence the performance of the motor.

The Assembly Process: Step-by-Step Guide

The assembly process of the 200 Watts DC Motor 220 Volt is a meticulous task. It requires precision, patience, and a deep understanding of electrical engineering principles.

Preparing the Components

The first step involves preparing the aluminium reels, screws, and magnet. This includes cleaning, measuring, and ensuring the quality of each component.

Assembling the Motor

The assembly process involves carefully placing the aluminium reels and screws in the motor casing. The magnet is then positioned strategically to create the necessary magnetic field.

Testing the Motor

Once the assembly is complete, the motor is tested under controlled conditions. This step is crucial to ensure the motor’s functionality and efficiency.

The Potential Impact of the Experiment

The successful execution of this experiment could revolutionize the way we perceive and use DC motors. It could pave the way for more energy-efficient and sustainable solutions in the electrical engineering field.

Conclusion

In conclusion, the experiment of making a 200 Watts DC Motor 220 Volt with 12 Aluminium Reels, 12 screws, and a magnet is a testament to the endless possibilities in the field of electrical engineering. It challenges conventional methods and opens up new avenues for innovation and sustainability.

Frequently Asked Questions

What is the role of the magnet in the motor?

The magnet creates the magnetic field necessary for the motor to function.

Why are aluminium reels used in this experiment?

Aluminium reels are used due to their high conductivity and lightweight nature.

How does the assembly process work?

The assembly process involves preparing the components, assembling the motor, and testing it under controlled conditions.

What is the potential impact of this experiment?

This experiment could revolutionize the way we perceive and use DC motors, paving the way for more energy-efficient and sustainable solutions.

Can this experiment be replicated?

Yes, with the right knowledge and resources, this experiment can be replicated.

What is the purpose of this experiment?

The purpose is to create a 200W DC motor that can run on 220V using 12 aluminium reels, 12 screws, and a magnet as the core components.

Is this motor suitable for beginners?

Yes, but it requires basic knowledge of electricity, magnetism, and safety precautions.

Why use aluminium reels instead of copper?

Aluminium is lighter, cheaper, and conducts electricity adequately for small-scale experiments, though less efficient than copper.

How many aluminium reels are needed?

A total of 12 aluminium reels are required to form the stator and windings.

What role do the 12 screws play?

The screws act as the structural supports and magnetic interaction points in the motor assembly.

Why is a magnet used in this motor?

The magnet provides the magnetic field necessary for the motor to convert electrical energy into mechanical motion.

What is the expected output of the motor?

The design aims for around 200 watts of DC power at 220 volts.

Can I use copper wire instead of aluminium reels?

Yes, copper will improve efficiency, but aluminium is more budget-friendly for experimental builds.

How should the aluminium reels be arranged?

They should be symmetrically positioned around the stator for balanced performance.

Do I need special tools to assemble it?

Basic tools like screwdrivers, pliers, and insulation tape are usually sufficient.

Is this motor safe to operate at home?

Yes, if handled with care, insulation, and proper protective gear. Avoid overloading.

How do I connect the motor to a power source?

Connect the DC supply leads to the terminals of the wound aluminium reels, ensuring polarity is correct.

Can this motor run household appliances?

No, it is mainly an experimental project, not intended for running large household devices.

How much does it cost to build this motor?

The cost varies, but generally low since it uses simple, inexpensive materials like aluminium and screws.

Can I scale up the design for higher power?

Yes, but larger magnets, stronger windings, and reinforced materials will be required.

How does the magnet interact with aluminium?

While aluminium is non-magnetic, it supports current flow and interacts with the magnet’s field through induced motion.

What type of magnet should I use?

A strong neodymium magnet or ferrite magnet works best for this experiment.

What is the lifespan of this homemade motor?

With careful use, it can last for many hours, but it is not designed for industrial durability.

Can I use this motor for a fan or small pump?

Yes, low-power devices such as miniature fans or pumps can be tested.

Does the motor need cooling?

For continuous operation, passive air cooling or a small fan is recommended.

What is the efficiency of this motor?

The efficiency is relatively low compared to industrial motors due to basic materials and design.

Can I generate electricity with this motor?

Yes, if mechanically rotated, it can act as a small generator producing DC output.

How do I test if the motor is working?

Apply power, check for rotation, and measure voltage/current with a multimeter.

Can I reverse the motor direction?

Yes, by swapping the polarity of the power supply leads.

How do I insulate the aluminium reels?

Use insulating tape or varnish to prevent short circuits between coils.

Is this motor eco-friendly?

Yes, since it reuses simple materials and consumes little energy.

Can students use this experiment for science fairs?

Absolutely, it is a great DIY project to demonstrate electromagnetism.

What voltage rating should I use for testing?

Begin testing with lower voltage (12V–24V DC) before applying full 220V.

Do I need a rectifier?

If running from AC mains, yes, a rectifier is needed to convert AC to DC.

What safety precautions should I take?

Wear insulated gloves, avoid touching live wires, and test at low voltages first.

Can this motor replace commercial motors?

No, this is a learning project, not a substitute for professionally built motors.